Tape Casting

One of the most well-known and used method to manufacture multilayered ceramic components is the doctor-blade tape casting technique. Glenn N. Howatt is regarded as the godfather of tape casting and established this processing method in 1947[1] and also filed the first patent in 1948[2]. A plentiful variety of electronic components like multilayer ceramic capacitors (MLCC), actuators (MLA), varistors (MLV) or tapes for low/high temperature cofired ceramics (LTCC, HTCC) can be manufactured.

Contents

Components of a tape caster

Tape casting machine

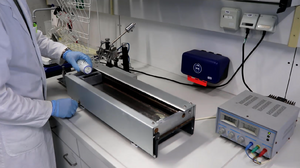

Tape casting machines are available in different scales. Usually big industrial companies have continuous tape casters with a length of several hundred meters. However, in academic research much smaller lab-scale tape casters are used which can range from half a meter to several meters in length.

Continuous as well as discontinuous tapes can be prepared with lab-scale tape casters. For continuous tapes, guide rollers and rollers with the carrier substrate are needed. If discontinuous tapes are produced, carrier substrate sheets can be used likewise.

The machines can be equipped with heating plates to keep the drying temperature constant. The ingredients of the slip need to be adjusted towards elevated temperatures to avoid rapid drying and bubbling. Solvents may evaporate much faster thereby degrading the green tape severly. It is recommended to use temperatures close to the room temperature.

Carrier substrate

Stainless steel belts as carrier substrates are most common in continuous manufacturing operations. It is economic and cost-effective. However, also Mylar, PTFE (Teflon), cellophane, silicone-coated polyester, and many other materials are suitable as well. Especially for lab-scales, Mylar sheets are easy to handle. If the tape caster The binder, solvent, and plasticizer system determines the interaction with the carrier material. The slip needs to wet the surface sufficiently and after drying the green tape needs to be peeled off well.

Reservoir

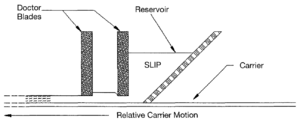

Doctor-blade

Other variables that come into play include reservoir depth, speed of carrier movement, viscosity of the slip, and shape of the doctor blade (to name just a few).

Drying chamber

Process of tape casting

Slip delivery

After mixing the slip system, air can be trapped within the slip. To remove remaining air bubbles and promote smooth and homogeneous green tapes without defects, a de-airing step is required. Putting the slip under vacuum will help to remove air. It needs to be noted that too high vacuum tends to let evaporate solvent. This will unbalance the weight ratios of the slip and change its rheological behavior. Subsequent to de airing the slip will be poured into the reservoir of the machine. Additional sieves can be used to prevent e.g. milling balls from falling into the reservoir. Before starting to cast the slip is supposed to be distributed in the reservoir.

Casting

The doctor-blade gap defines the wet thickness of the tape being cast. Either the substrate is stationary or the doctor-blade. The speed is supposed to be set in the range of 0.7 - 1 m/min.

Drying

Quality assessment

optical check, bubbles, orange peel, cracking, homogeneity, bendable, strechable, handable, homogeneous green sheet thickness, green density

References

- ↑ [1] Howatt, G.N., Breckenridge, R.G. and Brownlow, J.M. (1947), FABRICATION OF THIN CERAMIC SHEETS FOR CAPACITORS. Journal of the American Ceramic Society, 30: 237-242.

- ↑ [2] Howatt, G.N., Method of Producing High Dielectric High Insulation Ceramic Plates, U.S. Patent 2,582,993 (filed October 29, 1948).

- ↑ [3] Mistler, R.E. (1995), The principles of tape casting and tape casting applications. In: Terpstra, R.A., Pex, P.P.A.C., de Vries, A.H. (eds) Ceramic Processing. Springer, Dordrecht.