Difference between revisions of "Tape Casting"

| Line 4: | Line 4: | ||

== Components of a tape caster == | == Components of a tape caster == | ||

=== Tape casting machine === | === Tape casting machine === | ||

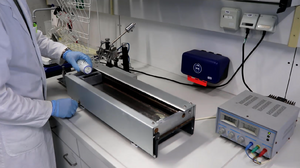

| − | Tape casting machines are assembled in different scales. Usually big industrial companies have continuous tape casters with a length of several hundred meters. However, in academic research much smaller lab-scale tape caster are used which can range from half a meter to several meters in length. [[File:Tape casting machine.png|thumb|Lab-scale doctor-blade tape caster. The slurry is poured into the reservoir before starting to cast.]] | + | Tape casting machines are assembled in different scales. Usually big industrial companies have continuous tape casters with a length of several hundred meters. However, in academic research much smaller lab-scale tape caster are used which can range from half a meter to several meters in length. [[File:Tape casting machine.png|thumb|Lab-scale doctor-blade tape caster. The slurry is poured into the reservoir before starting to cast.]] Continuous as well as discontinuous tapes can be prepared with lab-scale tape casters. For continuous tapes, guide rollers and rollers with the carrier substrate are needed. If discontinuous tapes are produced, carrier substrate sheets can be used likewise. |

| + | |||

| + | === Carrier substrate === | ||

| + | |||

| + | |||

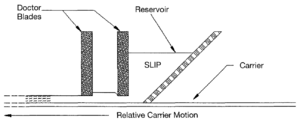

[[File:Schematic doctor blading.png|thumb|Schematic of the doctor-blade tape casting technique. The slip is poured in a reservoir and cast on a carrier. The doctor-blade height defines the green sheet's thickness.<ref>[https://doi.org/10.1007/978-94-011-0531-6_5] Mistler, R.E. (1995), The principles of tape casting and tape casting applications. In: Terpstra, R.A., Pex, P.P.A.C., de Vries, A.H. (eds) Ceramic Processing. Springer, Dordrecht.</ref>]] | [[File:Schematic doctor blading.png|thumb|Schematic of the doctor-blade tape casting technique. The slip is poured in a reservoir and cast on a carrier. The doctor-blade height defines the green sheet's thickness.<ref>[https://doi.org/10.1007/978-94-011-0531-6_5] Mistler, R.E. (1995), The principles of tape casting and tape casting applications. In: Terpstra, R.A., Pex, P.P.A.C., de Vries, A.H. (eds) Ceramic Processing. Springer, Dordrecht.</ref>]] | ||

| Line 10: | Line 14: | ||

=== Doctor-blade === | === Doctor-blade === | ||

=== Drying chamber === | === Drying chamber === | ||

| − | + | ||

== Process of tape casting == | == Process of tape casting == | ||

=== Slip delivery === | === Slip delivery === | ||

Revision as of 14:53, 27 October 2022

One of the most well-known and used method to manufacture multilayered ceramic components is the doctor-blade tape casting technique. Glenn N. Howatt is regarded as the godfather of tape casting and established this processing method in 1947[1] and also filed the first patent in 1948[2]. A plentiful variety of electronic components like multilayer ceramic capacitors (MLCC), actuators (MLA), varistors (MLV) or tapes for low/high temperature cofired ceramics (LTCC, HTCC) can be manufactured.

Contents

Components of a tape caster

Tape casting machine

Tape casting machines are assembled in different scales. Usually big industrial companies have continuous tape casters with a length of several hundred meters. However, in academic research much smaller lab-scale tape caster are used which can range from half a meter to several meters in length.

Continuous as well as discontinuous tapes can be prepared with lab-scale tape casters. For continuous tapes, guide rollers and rollers with the carrier substrate are needed. If discontinuous tapes are produced, carrier substrate sheets can be used likewise.

Carrier substrate

Reservoir

Doctor-blade

Drying chamber

Process of tape casting

Slip delivery

Casting

Drying

Quality assessment

optical check, bubbles, orange peel, cracking, homogeneity, bendable, strechable, handable, homogeneous green sheet thickness, green density

References

- ↑ [1] Howatt, G.N., Breckenridge, R.G. and Brownlow, J.M. (1947), FABRICATION OF THIN CERAMIC SHEETS FOR CAPACITORS. Journal of the American Ceramic Society, 30: 237-242.

- ↑ [2] Howatt, G.N., Method of Producing High Dielectric High Insulation Ceramic Plates, U.S. Patent 2,582,993 (filed October 29, 1948).

- ↑ [3] Mistler, R.E. (1995), The principles of tape casting and tape casting applications. In: Terpstra, R.A., Pex, P.P.A.C., de Vries, A.H. (eds) Ceramic Processing. Springer, Dordrecht.