Difference between revisions of "Tape Casting"

| Line 1: | Line 1: | ||

| − | One of the most well-known and used method to manufacture multilayered ceramic components is the doctor-blade tape casting technique. | + | One of the most well-known and used method to manufacture multilayered ceramic components is the doctor-blade tape casting technique. Glenn N. Howatt is regarded as the godfather of tape casting and established this processing method in 1947<ref>[https://doi.org/10.1111/j.1151-2916.1947.tb18889.x] Howatt, G.N., Breckenridge, R.G. and Brownlow, J.M. (1947), FABRICATION OF THIN CERAMIC SHEETS FOR CAPACITORS. Journal of the American Ceramic Society, 30: 237-242.</ref> and also filed the first patent in 1948<ref>[https://patents.google.com/patent/US2582993A/en] Howatt, G.N., Method of Producing High Dielectric High Insulation Ceramic Plates, U.S. Patent 2,582,993 (filed October 29, 1948).</ref>. A plentiful variety of electronic components like multilayer ceramic capacitors (MLCC), actuators (MLA), varistors (MLV) or tapes for low/high temperature cofired ceramics (LTCC, HTCC) can be manufactured. |

== Components of a tape caster == | == Components of a tape caster == | ||

=== Tape casting machine === | === Tape casting machine === | ||

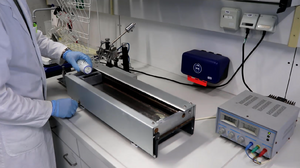

| + | Tape casting machines are assembled in different scales. Usually big industrial companies have continuous tape casters with a length of several hundred meters. However, in academic research much smaller lab-scale tape caster are used which can range from half a meter to several meters in length. [[File:Tape casting machine.png|thumb|Lab-scale doctor-blade tape caster. The slurry is poured into the reservoir before starting to cast.]] They also does not necessarily need to be continuous. Continuous tape | ||

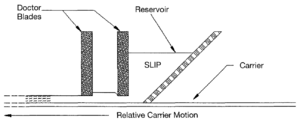

| + | [[File:Schematic doctor blading.png|thumb|Schematic of the doctor-blade tape casting technique. The slip is poured in a reservoir and cast on a carrier. The doctor-blade height defines the green sheet's thickness.<ref>[https://doi.org/10.1007/978-94-011-0531-6_5] Mistler, R.E. (1995), The principles of tape casting and tape casting applications. In: Terpstra, R.A., Pex, P.P.A.C., de Vries, A.H. (eds) Ceramic Processing. Springer, Dordrecht.</ref>]] | ||

=== Reservoir === | === Reservoir === | ||

Revision as of 14:42, 27 October 2022

One of the most well-known and used method to manufacture multilayered ceramic components is the doctor-blade tape casting technique. Glenn N. Howatt is regarded as the godfather of tape casting and established this processing method in 1947[1] and also filed the first patent in 1948[2]. A plentiful variety of electronic components like multilayer ceramic capacitors (MLCC), actuators (MLA), varistors (MLV) or tapes for low/high temperature cofired ceramics (LTCC, HTCC) can be manufactured.

Contents

Components of a tape caster

Tape casting machine

Tape casting machines are assembled in different scales. Usually big industrial companies have continuous tape casters with a length of several hundred meters. However, in academic research much smaller lab-scale tape caster are used which can range from half a meter to several meters in length.

They also does not necessarily need to be continuous. Continuous tape

Reservoir

Doctor-blade

Drying chamber

Carrier and substrate

Process of tape casting

Slip delivery

Casting

Drying

Quality assessment

optical check, bubbles, orange peel, cracking, homogeneity, bendable, strechable, handable, homogeneous green sheet thickness, green density

References

- ↑ [1] Howatt, G.N., Breckenridge, R.G. and Brownlow, J.M. (1947), FABRICATION OF THIN CERAMIC SHEETS FOR CAPACITORS. Journal of the American Ceramic Society, 30: 237-242.

- ↑ [2] Howatt, G.N., Method of Producing High Dielectric High Insulation Ceramic Plates, U.S. Patent 2,582,993 (filed October 29, 1948).

- ↑ [3] Mistler, R.E. (1995), The principles of tape casting and tape casting applications. In: Terpstra, R.A., Pex, P.P.A.C., de Vries, A.H. (eds) Ceramic Processing. Springer, Dordrecht.